回轉窯配件大齒輪

2022/2/14

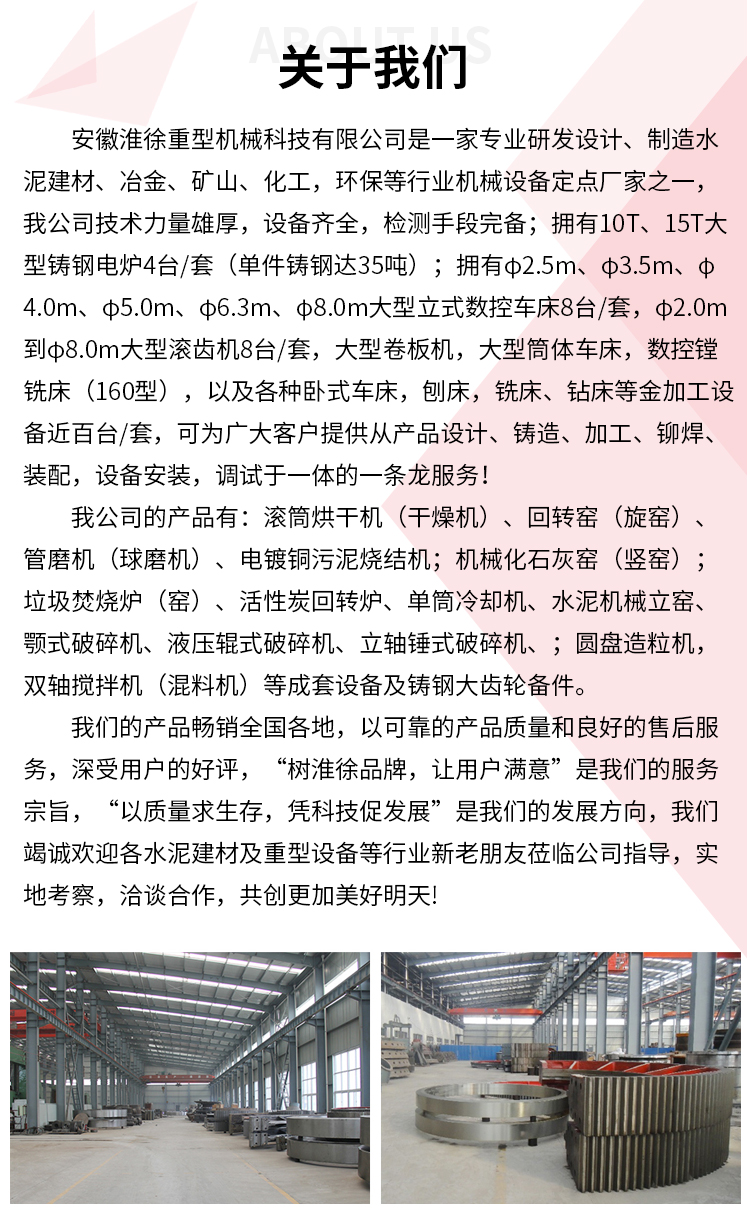

回轉窯是指旋轉煅燒窯(俗稱旋窯),它廣泛應用于黑色冶金、有色冶金、化工、建材(水泥)、非金屬礦、耐火材料、造紙、環保等行業,回轉窯按處理物料不同可分為水泥窯、冶金化工窯和石灰窯。在建材行業中回轉窯用來煅燒水泥熟料,分干法生產水泥回轉窯和濕法生產水泥回轉窯兩大類;在冶金行業中鋼鐵廠貧鐵礦磁化焙燒;鉻、鎳鐵礦氧化焙燒;耐火材料廠焙燒高鋁釩土礦和鋁廠焙燒熟料、氫氧化鋁;,回轉窯用于生產氧化鐵球團、鐵精礦直接還原、超細鐵精礦及高爐灰的回收利用;化工行業中回轉窯可用于進行生產鈦白粉、氧化鎂、氧化鋅的培燒,用于高鋁釩土、氟化鹽及鋁廠用于氫氧化鋁的培燒,活性石灰和輕燒白云石的煅燒,陶粒廠用于燒制陶粒砂.。

回轉窯由回轉筒體(ti)、支承(cheng)(cheng)裝(zhuang)(zhuang)(zhuang)置(zhi)(zhi)(zhi)、帶擋(dang)輪(lun)支承(cheng)(cheng)裝(zhuang)(zhuang)(zhuang)置(zhi)(zhi)(zhi)和窯頭、窯尾(wei)密封裝(zhuang)(zhuang)(zhuang)置(zhi)(zhi)(zhi)、噴煤管裝(zhuang)(zhuang)(zhuang)置(zhi)(zhi)(zhi)等部(bu)分組(zu)成。窯體(ti)與(yu)水平呈一(yi)定的斜度,整個窯體(ti)由托輪(lun)裝(zhuang)(zhuang)(zhuang)置(zhi)(zhi)(zhi)支承(cheng)(cheng),并有控(kong)制窯體(ti)上下竄動(dong)(dong)的擋(dang)輪(lun)裝(zhuang)(zhuang)(zhuang)置(zhi)(zhi)(zhi)。傳(chuan)(chuan)動(dong)(dong)部(bu)分除設(she)置(zhi)(zhi)(zhi)主傳(chuan)(chuan)動(dong)(dong)外,還設(she)置(zhi)(zhi)(zhi)了為保(bao)障在主傳(chuan)(chuan)動(dong)(dong)電(dian)源(yuan)中斷(duan)時仍能使(shi)窯體(ti)慢(man)速轉動(dong)(dong)、防(fang)止窯體(ti)變形的輔(fu)助傳(chuan)(chuan)動(dong)(dong)裝(zhuang)(zhuang)(zhuang)置(zhi)(zhi)(zhi)。窯頭采用(yong)殼罩式(shi)(shi)密封,窯尾(wei)裝(zhuang)(zhuang)(zhuang)有軸向接觸式(shi)(shi)密封裝(zhuang)(zhuang)(zhuang)置(zhi)(zhi)(zhi),保(bao)證了密封的可靠性!

|

產品規格(m) |

窯體尺寸 |

產量(liang)(t/d) |

轉速(su)(r/min) |

電機功率(lv)(kw) |

總重量(t) |

備注 |

||

|

直徑(jing)(m) |

長度(m) |

斜度(%) |

||||||

|

|

|

|

|

|

|

|

|

|

|

Φ2.5×40 |

2.5 |

40 |

3.5 |

180 |

0.44-2.44 |

55 |

149.61 |

|

|

Φ2.5×50 |

2.5 |

50 |

3 |

200 |

0.62-1.86 |

55 |

187.37 |

---- |

|

Φ2.5×54 |

2.5 |

54 |

3.5 |

280 |

0.48-1.45 |

55 |

196.29 |

窯外(wai)分解窯 |

|

Φ2.7×42 |

2.7 |

42 |

3.5 |

320 |

0.10-1.52 |

55 |

198.5 |

---- |

|

Φ2.8×44 |

2.8 |

44 |

3.5 |

450 |

0.437-2.18 |

55 |

201.58 |

窯外分解窯 |

|

Φ3.0×45 |

3 |

45 |

3.5 |

500 |

0.5-2.47 |

75 |

210.94 |

---- |

|

Φ3.0×48 |

3 |

48 |

3.5 |

700 |

0.6-3.48 |

100 |

237 |

窯外分(fen)解窯 |

|

Φ3.0×60 |

3 |

60 |

3.5 |

800 |

0.3-2 |

100 |

310 |

|

|

Φ3.2×50 |

3.5 |

50 |

4 |

1000 |

0.6-3 |

125 |

278 |

窯外分解窯 |

|

Φ3.3×52 |

3.3 |

52 |

3.5 |

1300 |

0.266-2.66 |

125 |

283 |

預熱(re)分解窯 |

|

Φ3.5×54 |

3.5 |

54 |

3.5 |

1500 |

0.55-3.4 |

220 |

363 |

預(yu)熱分解窯 |

|

Φ3.6×70 |

3.6 |

70 |

3.5 |

1800 |

0.25-1.25 |

125 |

419 |

余熱發電窯 |

|

Φ4.0×56 |

4 |

56 |

4 |

2300 |

0.41-4.07 |

315 |

456 |

預熱分解(jie)窯 |

|

Φ4.0×60 |

4 |

60 |

3.5 |

2500 |

0.396-3.96 |

315 |

510 |

預熱分(fen)解窯(yao) |

|

Φ4.2×60 |

4.2 |

60 |

4 |

2750 |

0.41-4.07 |

375 |

633 |

預熱分解窯(yao) |

|

Φ4.3×60 |

4.3 |

60 |

3.5 |

3200 |

0.396-3.96 |

375 |

583 |

預熱(re)分(fen)解窯 |

|

Φ4.5×66 |

4.5 |

66 |

3.5 |

4000 |

0.41-4.1 |

560 |

710.4 |

預(yu)熱分解(jie)窯 |

|

Φ4.7×74 |

4.7 |

74 |

4 |

4500 |

0.35-4 |

630 |

849 |

預熱分解(jie)窯 |

|

Φ4.8×74 |

4.8 |

74 |

4 |

5000 |

0.396-3.96 |

630 |

899 |

預熱(re)分解窯 |